Innovation

From biopsy to personalized bioengineered skin and innovation for medicine and industry

Development

The skin is the largest organ of the human body. It protects the whole body and performs various vital functions. Its damage can lead to a protracted healing process. A severe skin burn, skin loss or chronic skin disease is often associated with multiple surgeries and defacements. Patients suffer physiologically and psychologically.

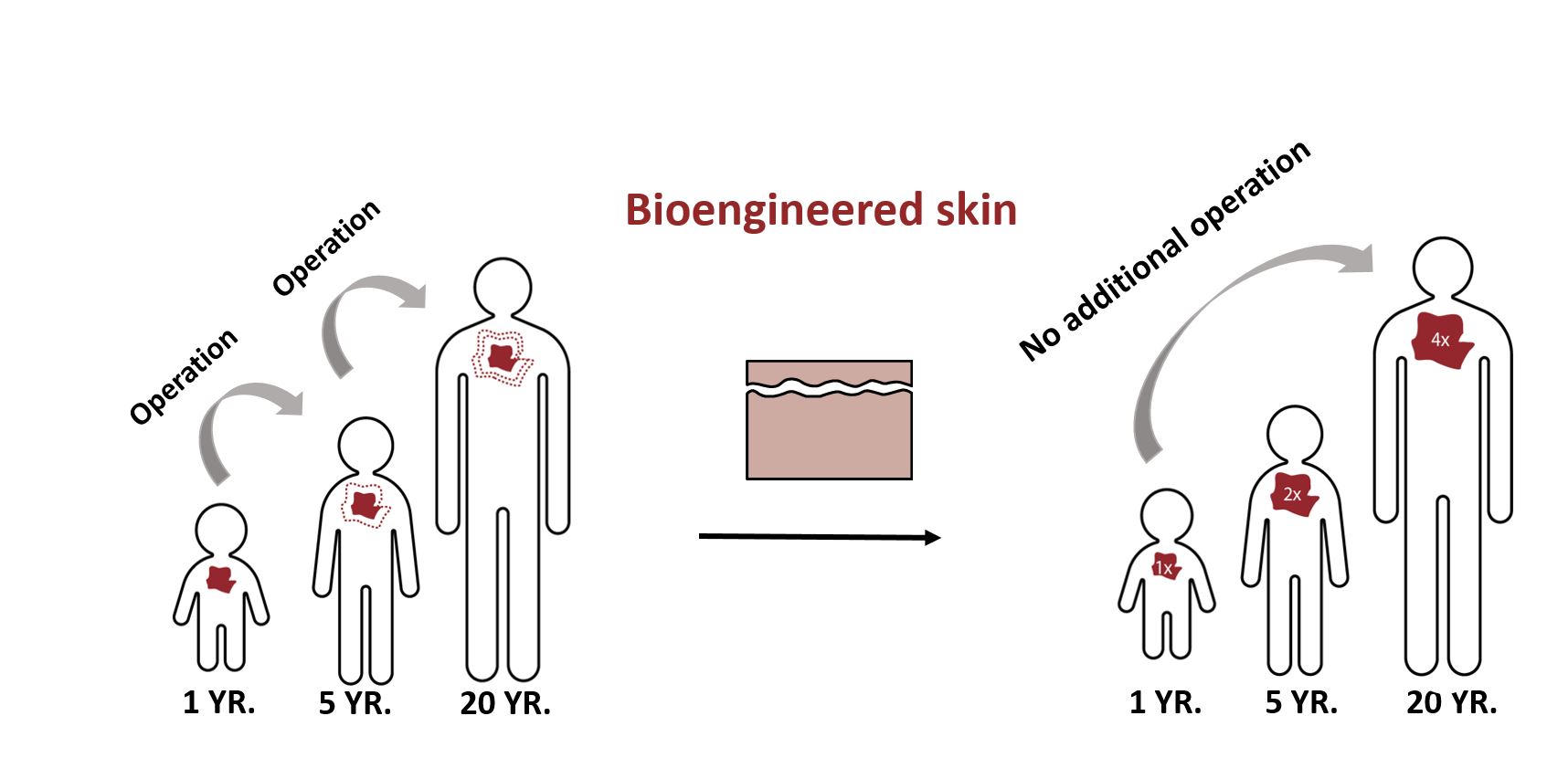

Children with severe burns suffer for a long time

Today’s Gold Standard to treat severe burns is a split skin transplantation using the patient's own skin transplanted to the burnt area. However, the downside of this method is that this procedure results in a non-elastic transplanted skin. Dependent on where the burnt area is located, children need a new transplantation every 2-3 years until they are fully-grown. Every operation means new physical, psychological and financial burden for the patient. The novel bio-engineered skin developed by the Tissue Biology Research Unit in Zurich may well open new avenues in surgical treatment.

Other applications

Adults will also benefit from this new device even though they do not require skin transplants that grow after transplantation. The goal of the SkinReactor is to allow individual cell proliferation for screenings for disease treatment e.g. cancer.

The new type of skin developed at the TBRU, supervised by Prof. E. Reichmann, has the advantage of growing after the transplantation. Several transplantations on children performed by the clinical partner, the University-Children’s Hospital in Zurich, led to very promising results. As a next step, this treatment has to enter phase II clinical studies now.

Automatisation allows the same treatment for everyone

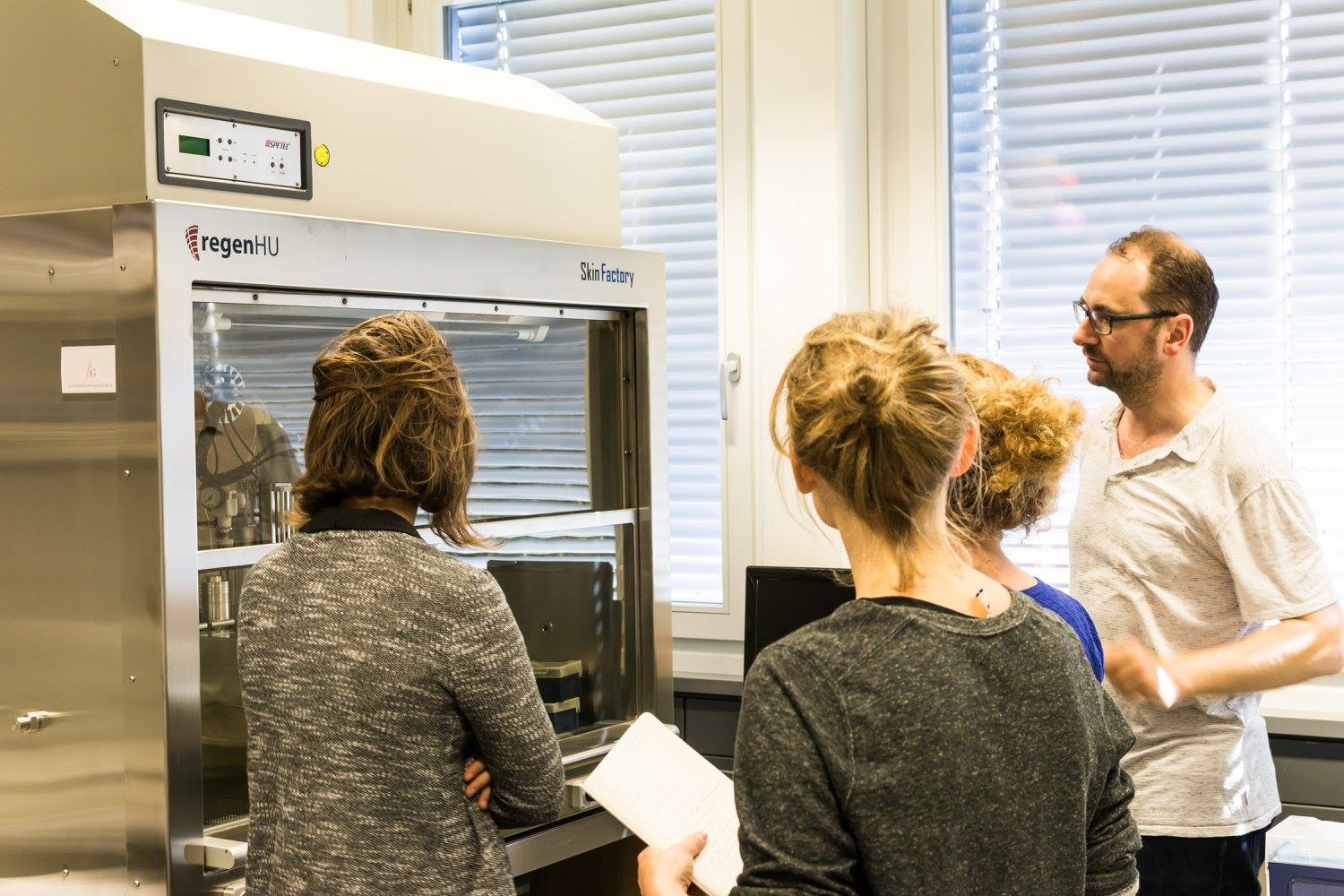

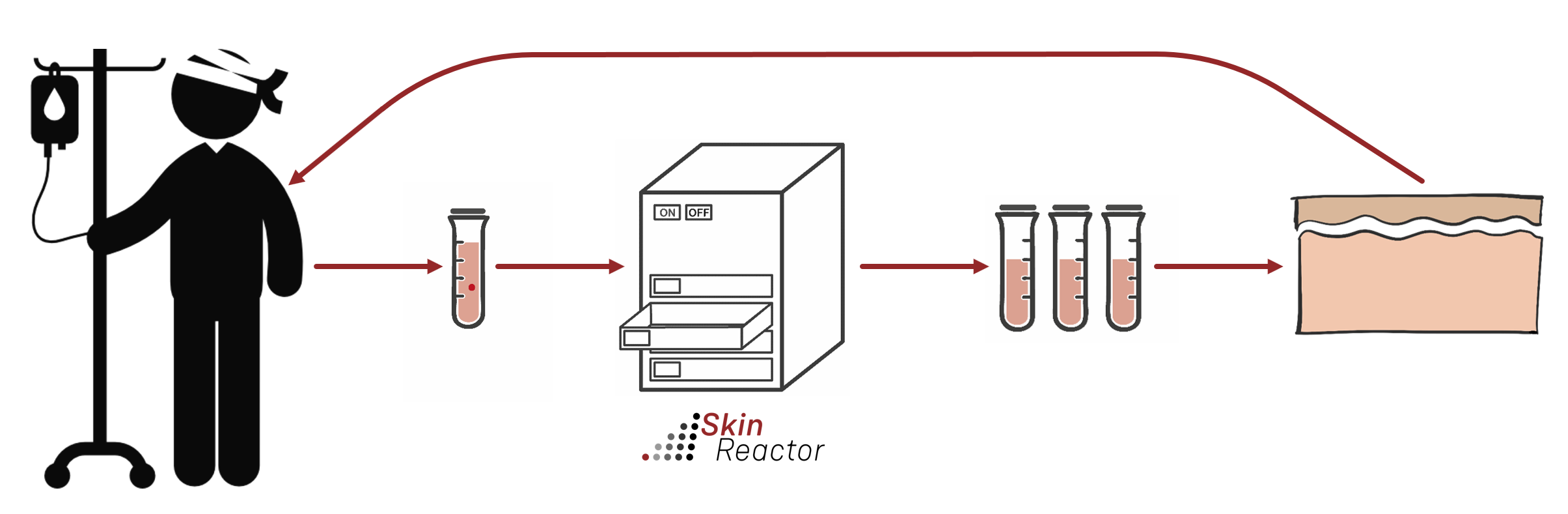

The goal of our project is to develop a bio-reactor optimized for proliferation of patient individual cells for bioengineered skin.

What is the advantage of the automation? Traditional methods require expensive lab infrastructure, highly qualified employees, highly specialized materials and are time consuming. We have a dream that one day, every severe burnt child around the world has access to be cured by bioengineered skin through cost effective and robust automation.

How does our SkinReactor work?

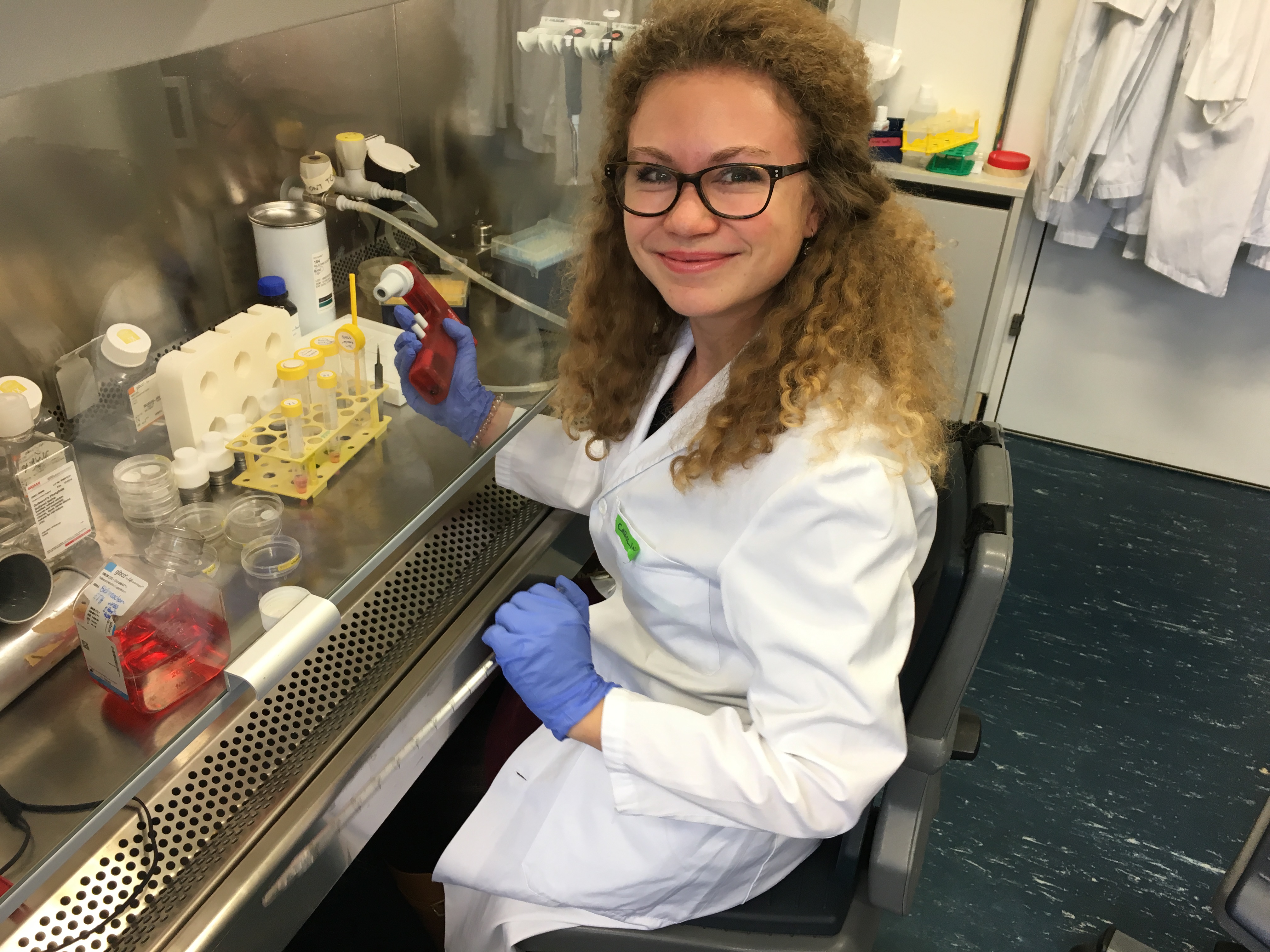

First, a stamp sized biopsy is taken from the patient which afterwards gets split into cells and brought into our machine. Our device automatically cultures these cells up to a number enough to create in a further production step the transplantable skin equivalent. The surgeon uses this patch for a transplant. Our bioreactor is tailored to the needs of skin cell proliferation in personalized medicine.

Future

We expect a future where tissue engineered skin is easily available. For this, cell proliferation is the crucial process. Without cell proliferation there is no bioengineered skin patch. This step is the longest, technical the most complex and therefore we focus on this one first.

Development

We build completely new type of machine from scratch

UI/UX

We love creating beautiful and functional machines for future use

Sponsoring

Finding sponsors to support our project is one of the main tasks. R&D is expensive

System Design

Different cells have different needs. We design our machine to address them

Cell replication

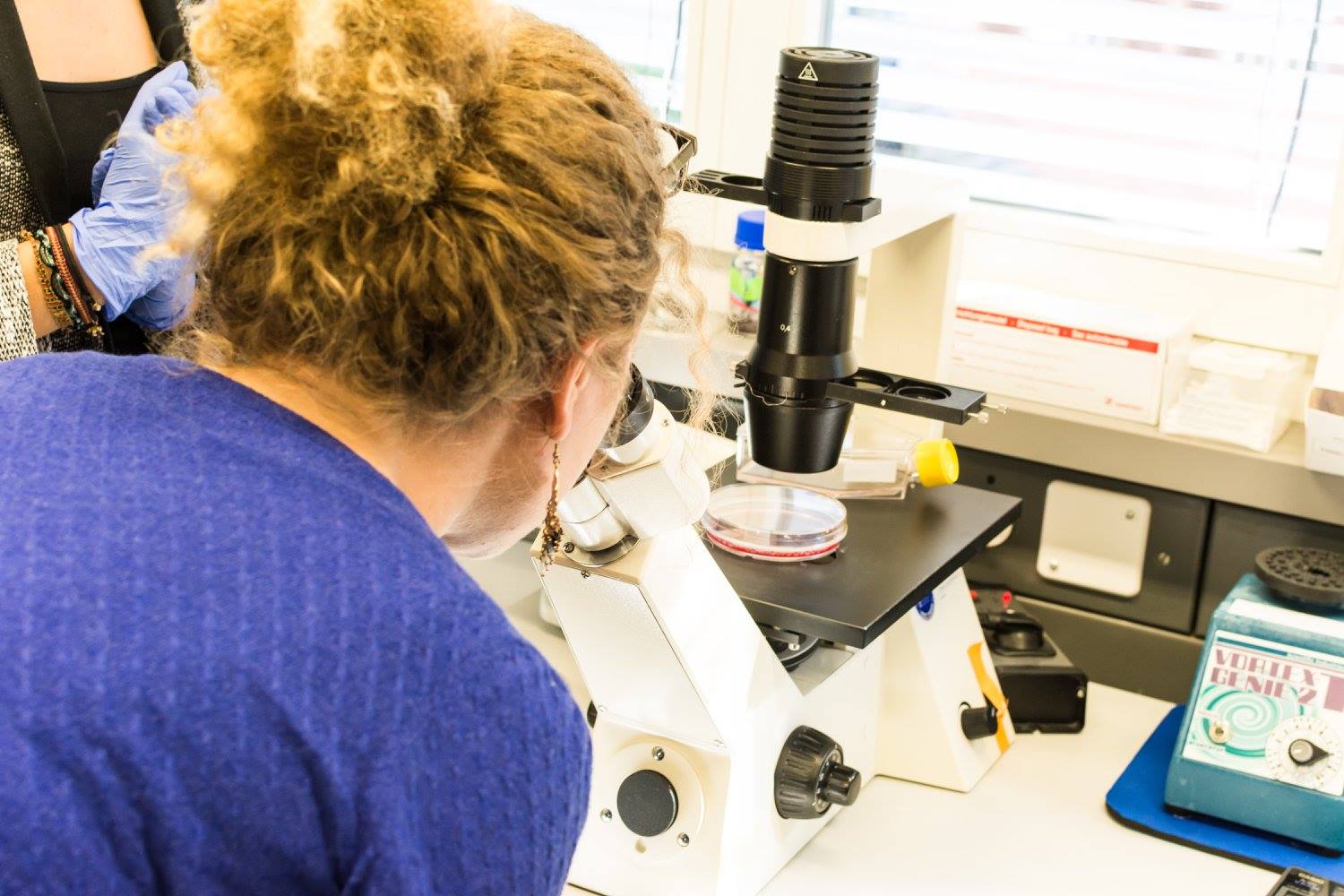

We're about to find easier and more robust ways to replicate cells and harvest them

Research

Addressing the emerging needs of biofabrication for tissue engineering.